小渕研究室 (G30)

Interdisciplinary design research connecting architecture, engineering, and computations to explore the emerging discourses on architecture and urbanism

Research Theme: Inclusive Digital Fabrication

In the past 20 years, digital fabrication played a major role in shaping the discourse of architecture. As an alternative to the mass-production for the mass consumption society, where the quality of differences is replaced with sameness, digital fabrication offered architectural spaces as a bespoken for a specific user or its context.

Our ambition is to develop fabrication systems that maximize the potential of technological advancement not only to increase the productivities but also to create a system that include all participants in our society.

u-tokyo.ac.jp/focus/en/articles/z0113_00224

We are currently exploring three areas of inclusive digital fabrication:

1. Haptic Digital Fabrication

2. Animal Digital Fabrication

3. Material Life Cycle Digital Fabrication

Haptic Digital Fabrication

t-ads.org/dfl/pavilion-paff-projectile-acoustic-fibre-forest

Can the integration of digital technologies in design and construction processes be used for expressing personal tendencies through the creation of new architectural practices as well as novel aesthetics?

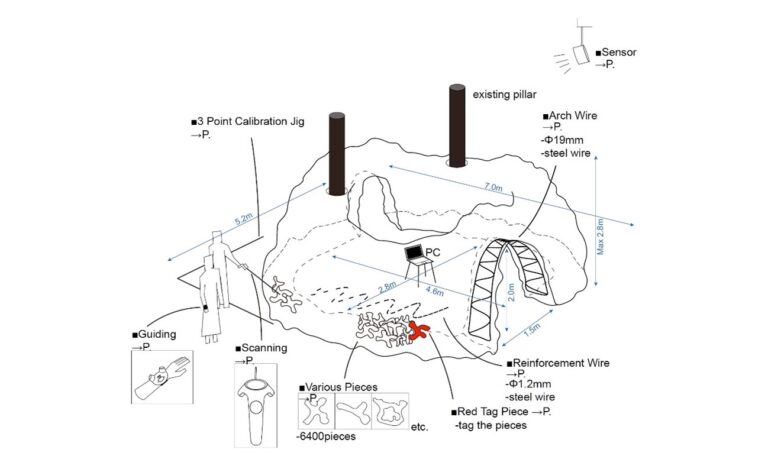

PAFF is an architecture made by reference to sound rather than visual information. We developed a sound guidance system whereby a worker’s task is to recognize a sound source in a three-dimensional space, and shoot fibers into various targets. PAFF is expressed through the accumulation of the multi-agent system, revealing personal differences in the way that people perceive space through sound.

Animal Digital Fabrication

seoulbiennale.org/exhibition/t19

Goldfish Architecture is a digitally augmented, functional vernacular construction that harnesses the therapeutic effects of plants and aqueous pets to propose a future for mindful and sustainable living. The proposed pavilion serves as a prototype for a productive and captivating smart aquaponic appliance that brings together households and communities alike. Our developed system effectively improves local air quality by taking advantage of the IoT-sustained microbiomes that stabilize humidity, filter VOCs, and lower CO2 levels. Through individual engagement, the user cultivates their mental and physical health by becoming a part of the growth cycle of the edible plants and the goldfish, representatives of peace and prosperity.

Material Lifecycle Digital Fabrication

forty-five.com/papers/arms-race

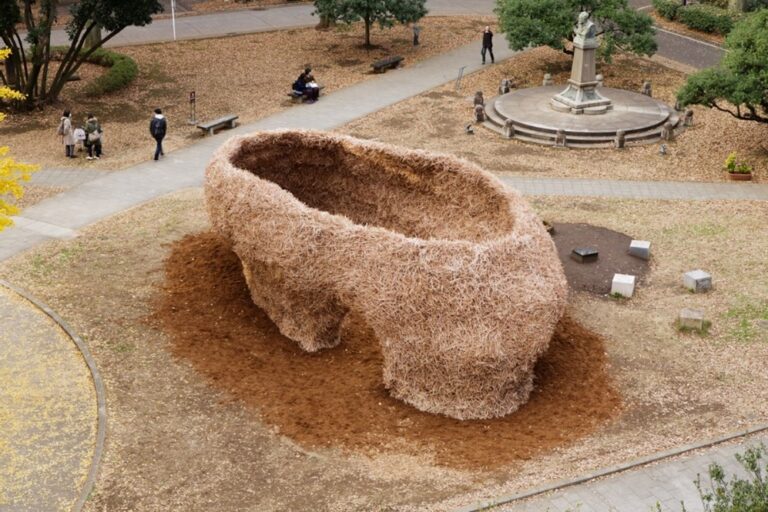

For the STIK project, we focused collectively on the development of a scaled-up version of a 3‑D printer that would utilize chopsticks. The latter material was chosen because, in large quantities, it is capable of behaving like particles, can be aggregated, and can be solidified using adhesives. Additionally, its scale as an aggregate is more conducive to production of a building, unlike the smaller-scale materials used in conventional 3‑D printers. To accommodate our material, we also wanted to make a fabrication tool capable of augmenting human capabilities through enhanced networking, which we called a network tool.