Hydro-Pressure Testing Apparatus for Material Fracture

実験セットアップおよび木材の破壊状況

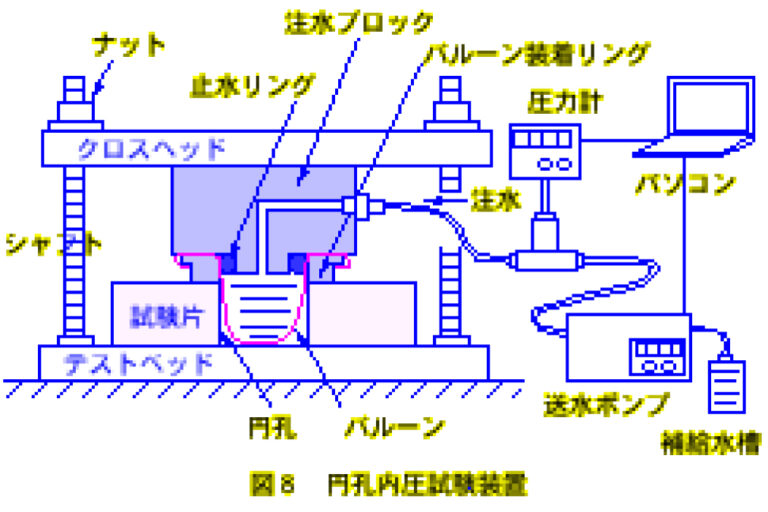

円孔内圧試験装置

This testing apparatus is invented to know the fracture strength of material without friction. Water is introduced into a circular hole of the tested material through a pipe and an attachment block by a hydraulic pump. The rubber balloon inserted in the hole in advance is stretched by the hydrostatic pressure and contacts on the surface wall of the hole without friction due to the rubber flexibility. The interior pressure is uniform on the basis of Pascal’s principle. The pressure at the onset of fracture of the test specimen provides the strength of the material. In the case of wood as shown in the photos, the pressure at the fracture is about 5MPa, which is equivalent to the pressure of 500-m water depth.

This testing apparatus has the above-mentioned advantage that the fracture strength is precisely measured without friction, which is often involved in the ordinary mechanical loading test.

Furthermore, this apparatus will be applied to the followings: (1) be applied to thick material without increasing the capacity of the pump; (2) be applied to on-site structural material with some improvements of mobility; (3) be applied to composite materials, concrete, and others; (4) be applied to arbitrary shapes of hole with a change of the attachment; and (5) be applied to water-soaked material when the balloon is removed.

It must be noted that air instead of water should not be used because of the danger of explosion. The water is safe even when the balloon is broken, because water is incompressive.